A maintenance plan defines when a pre-planned preventive maintenance job is to be carried out on an asset. Maintenance plans can be related to assets, asset types, functional locations, or functional location types, but first you create the maintenance plans to be used in your company.

A maintenance plan can have multiple maintenance plan lines. Maintenance job type and interval are specified on the maintenance plan line. There are two types of maintenance plan lines:

Maintenance plan lines of type "Time" are used for recurring planned maintenance based on a fixed time interval. Maintenance plan lines of type "Counter" are used for planned maintenance or reactive maintenance based on asset counter registrations. A maintenance plan may include several maintenance plan lines of both types.

If no counter values have been registered for a counter type on an asset, the maintenance plan lines are omitted.

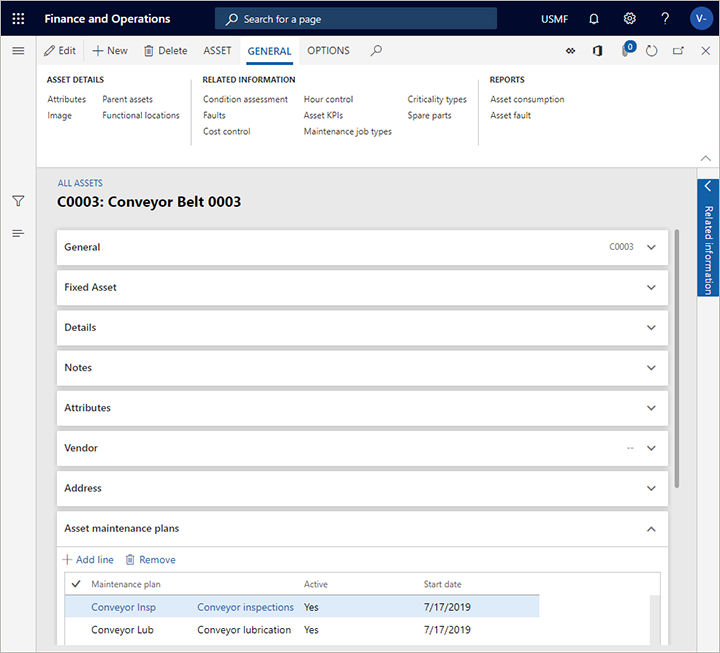

First, you create the maintenance plans you require for your preventive maintenance jobs and select the asset types, assets, functional location types, and functional locations that should be related to each maintenance plan. Afterwards, if required, you can also add maintenance plans to an asset or a functional location, which is done in All assets > select asset > Asset maintenance plans FastTab, or All functional locations > select functional location > Maintenance plans FastTab.

If you add a maintenance plan to asset types or functional location types, it means that when you create new assets or functional locations with those asset types or functional location types, the asset or functional location will automatically be added to the maintenance plan. The start date of the relation to a maintenance plan will be the current date, which may need to be adjusted.

This section describes how to set up maintenance plan lines and provides examples of how they can be used.

Note If you deactivate a maintenance plan, no schedule posts will be created in the maintenance schedule when you run a schedule maintenance plan job.

Note The example described in this and the previous step means that if several maintenance plan lines overlap, and Suppress overlapping maintenance jobs is selected for one or more lines, the period of omitting maintenance schedule lines is extended to a total of five days (the expected start date on the maintenance schedule line and two days before and two days after that date).

Note The example described in this step shows that the most comprehensive job, which contains the largest number of tasks, and which is not done so often, should always be inserted as the first line. The more frequent jobs are then inserted as separate lines in the order of frequency, placing the most frequent job at the bottom of the list.

Example: If counter registrations are expected to be made once a month, you may insert the number '365' in this field because maintenance plan scheduling will always be based on the last 12 months and therefore create maintenance schedule lines based on the trend of the past year. On the other hand, if you insert the number '10' in this field, you expect counter registrations to be made more often, for example, on a daily basis. This means that when you schedule maintenance plan, counter registrations for the last 10 days are used as the basis for the scheduling of maintenance schedule lines.

When work orders are manually created on assets that are covered by a vendor warranty, a dialog box is shown to make the user aware of the warranty. The creation of the work order can then be canceled. The check for a warranty relation is omitted for work orders that are automatically created.

| Interval type and description | Line Type: Time | Line Type: Counter |

|---|---|---|

| Interval type: Repeated from plan date The count starts from the plan date used. When you schedule maintenance plans, maintenance schedule lines are created when the interval is reached. | The Plan date on the maintenance plan line is used. If no plan date is selected on the line, the Plan date for the maintenance plan is used. Example: If the number "3" is inserted in the Period frequency field, and "Year" is selected in the Period field, a new maintenance schedule line will be created once every 3 years. | The Plan date for the maintenance plan is used. If the counter has been replaced, the latest replacement date is used as the plan date. |

| Interval type: Repeated from start date The count starts from the start date on the asset relation. The date is selected in the All asset details view > Asset maintenance plans FastTab > Start date field, or in the All functional locations details view > Maintenance plans FastTab > Start date field. When you schedule maintenance plans, a maintenance schedule line is created when the interval is reached. | The start date of the maintenance plan line on asset or functional location is used. If that field is blank, the Plan date for the maintenance plan is used. | The start date of the maintenance plan line on asset or functional location is used. If that field is blank, the Plan date for the maintenance plan is used. |

| Interval type: Repeated from last work order The count starts from the actual end date and time of the latest work order that was completed on the asset with that specific maintenance job type / maintenance job type variant / trade combination. That date and time are shown in the Actual end field in the All work order details view. | The actual end date and time of the work order completed on the asset with that specific maintenance job type / maintenance job type variant / trade combination. If no completed work order is found, one of the dates used in the "Repeated from start date" interval type is used instead. | The actual end date and time of the work order completed on the asset and the maintenance job type / maintenance job type variant / trade combination. is used. If the end date and time was left blank on the work order, one of the dates used in the "Repeated from start date" interval type is used instead. |

| Interval type: Once from plan date See description for the "Repeated from plan date" interval type. Only difference is that this interval type is to be used only once. | See description for "Repeated from plan date" interval type. This interval is typically used for a one-time maintenance or service job. | See description for "Repeated from plan date" interval type above. This interval is typically used for a one-time maintenance or service job. Note 1: This interval type is only relevant if the counter is replaced every time you carry out a maintenance or service job. If, for some reason, a counter has been replaced before the end of the planned interval, a new time is calculated for the job from the time of the counter replacement. Note 2: If the counter is replaced when completing the maintenance or service job, this interval type functions as the "Repeated from plan date" interval type. |

| Interval type: Once from start date See description for the "Repeated from start date" interval type. Only difference is that this interval type is to be used only once. | See description for "Repeated from start date" interval type. This interval is typically used for a one-time maintenance or service job. | See description for "Repeated from start date" interval type. This interval is typically used for a one-time maintenance or service job. Note 1 above also applies to this interval type. Note 3: If the counter is replaced when completing the maintenance or service job, this interval type functions as the "Repeated from start date" interval type. |

| Interval type: Once reached above This interval type only relates to counters and is used for indicating an upper limit set up on the maintenance plan line. Maintenance schedule entries will have the expected start date and time of the counter registration, meaning these entries will be created with an expected start date equal to or earlier than the system date. | Not applicable | The counter interval indicates an upper limit. If that limit is exceeded when you create a counter registration, a maintenance schedule line is created when you schedule preventive maintenance. |

| Interval type: Once reached below This interval type only relates to counters and is used for indicating a lower limit set up on the maintenance plan line. Maintenance schedule entries will have the expected start date and time of the counter registration, meaning these entries will be created with an expected start date equal to or earlier than the system date. | Not applicable | The counter interval indicates a lower limit. If that limit is passed when you create a counter registration, a maintenance schedule line is created when you schedule preventive maintenance. |

| Interval type: Linked from start date This interval type only creates a maintenance schedule line once. A maintenance plan can contain more maintenance plan lines using this interval type, and those lines are linked. Typically, you'll create a maintenance plan that contains lines of only this interval type. Maintenance schedule lines are created by identifying the maintenance plan line that has the first expected start date and time. | See description for "Once from start date" above. Example: You create two lines in a maintenance plan for a service job on a car: one time-based line with a 1-year period, and one counter-based line with a 25,000 km limit. A maintenance schedule line is created for the limit that is reached first. For this line type you create the line with the 1-year period. | See description for "Once from start date" above. Example: You create two lines in a maintenance plan for a service job on a car: one time-based line with a 1-year period, and one counter-based line with a 25,000 km limit. A maintenance schedule line is created for the limit that is reached first. For this line type, you create the line with the 25,000 km limit. Example creating two counter lines: You can also set up a maintenance plan with two linked, counter-based lines in which the first line has a limit of 10,000 items quantity produced, and the second line relates to the machine or work center requiring service after running 3,000 hours. |

| Interval type: Linked from last work order This interval type creates new maintenance schedule lines after every completed work order. A maintenance plan can contain more lines using this interval type, and those lines are linked. Typically, you'll create a maintenance plan that contains maintenance plan lines of only this interval type. Maintenance schedule lines are created by identifying the maintenance plan line that has the first expected start date and time. | This interval type basically works as "Linked from start date" described above. Only difference is the date on which the interval type is based. The date used is the actual date and time on the latest work order completed on the asset and the maintenance job type / maintenance job type variant / trade combination. | This interval type basically works as "Linked from start date" described above. Only difference is the date on which the interval type is based. The date used is the actual date and time on the latest work order completed on the asset and the maintenance job type / maintenance job type variant / trade combination. |

| Interval type: Repeated on aggregated value (Counter only) When the maintenance plan is run, a scheduled maintenance line will be created each time that the accumulated value for an asset counter reaches the period frequency or an even multiple of the period frequency. (The period frequency is defined on the maintenance plan line.) |

For more information about how to enable and use this functionality, see the Counter-based maintenance enhancements section later in this article.

For more information about how to enable and use this functionality, see the Counter-based maintenance enhancements section.

When maintenance schedule lines are created for time-based maintenance plan lines, expected time is always at the start of the day. For counter-based maintenance plan lines, expected time can be anytime during the day.

Here are some examples of how to set up time-based and counter-based maintenance plan lines:

Example 1 - Time-based maintenance plan line: A lubrication job is set up in a fixed interval, occurring once a week. For that purpose, select "Repeated from plan date" in the Interval type field. See an example in the following illustration.

Example 2 - Time-based maintenance plan line: An inspection job is set up to be carried out approximately once a week. For that purpose, select "Repeated from last work order" in the Interval type field. See an example in the following illustration.

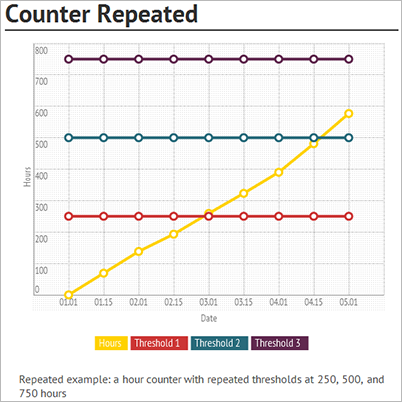

Example 3 - Counter-based maintenance plan line: The following graphic illustration shows an hour counter for which a new maintenance schedule line is created each time 250 hours have passed. The interval type for this counter-based line is "Repeated from start date". The start date is the start date of the related assets in the All assets details view > Asset maintenance plans FastTab > Start date field, or in the Functional location details view > Maintenance plans FastTab > Start date field. This is an example of a preventive maintenance plan because the maintenance schedule line is automatically created each time the threshold (+ 250) is reached.

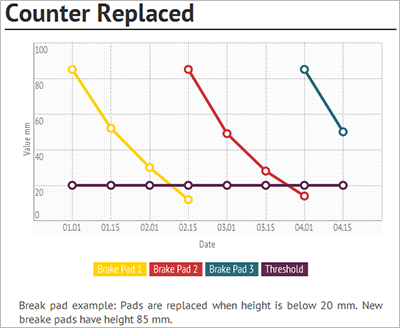

Example 4 - Counter-based maintenance plan line: The following graphic illustration shows a decrease in counter value, measuring brake pad wear. A maintenance schedule line is created when a counter registration below 20 mm is created on the brake pad. The interval type for this counter-based line is "Once reached below" or "Once from last start date". This is an example of a reactive maintenance plan because the maintenance schedule line isn't created until a measurement below 20 mm is registered.

A decrease in counter value, measuring brake pad wear." />

A decrease in counter value, measuring brake pad wear." />

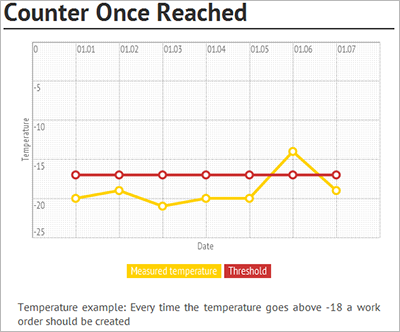

Example 5 - Counter-based maintenance plan line: The following graphic illustration shows a counter with a threshold of -18° Celsius. A maintenance schedule line is created when a counter registration above -18° Celsius is made. The interval type for this counter-based line is "Once reached above". This is an example of a reactive maintenance plan because the maintenance schedule line isn't created until a measurement higher than -18° Celsius is registered.

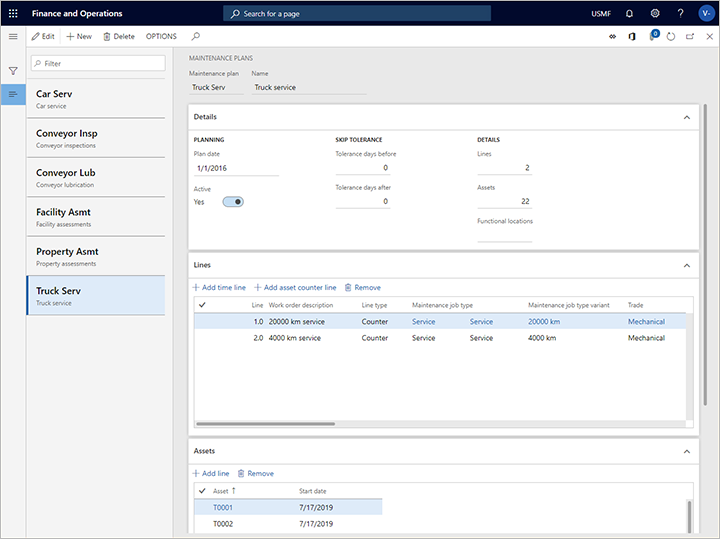

The following illustration shows an example of a "Truck service" maintenance plan on the Maintenance plans page.

The following illustration shows an example of maintenance plans set up on an asset on the All assets page.

The Counter-based maintenance enhancements feature introduces the following functionality:

To use this feature, it must be turned on for your system. As of Supply Chain Management version 10.0.32, it's turned on by default. Admins can turn this functionality on or off by searching for the Counter-based maintenance enhancements feature in the Feature management workspace.

Each time that you create an asset, related asset counters that are initialized to a value of 0 (zero) can automatically be created, provided that you set up your system and create the asset correctly.

When initialized asset counters are created, the assumption is that the asset had never been used before it was added to the system. When the maintenance schedule is run for the first time, the calculation uses the date and the 0 (zero) counter value as a baseline for calculating future maintenance. If the asset wasn't new when it was added to the system, you can manually adjust the counter value so that it matches the actual counter value. To adjust a counter value, open the relevant asset on the All assets page, and then, on the Action Pane, on the Asset tab, in the Preventative group, select Counters. On the Asset counters page for the selected asset, adjust the value in the Value column for the initial counter record as required.

You can configure the system to automatically reset a counter each time that a relevant work order reaches a selected status value.